Your issues

You need a higher throughput capacity

Your process is not fast enough

Your laser system reaches its limits

Product overview

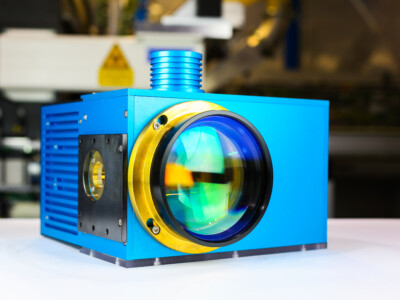

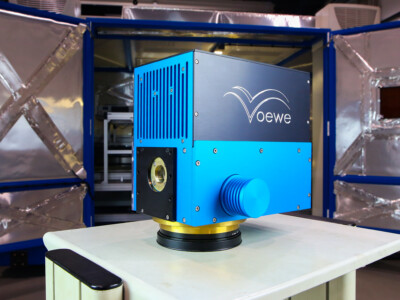

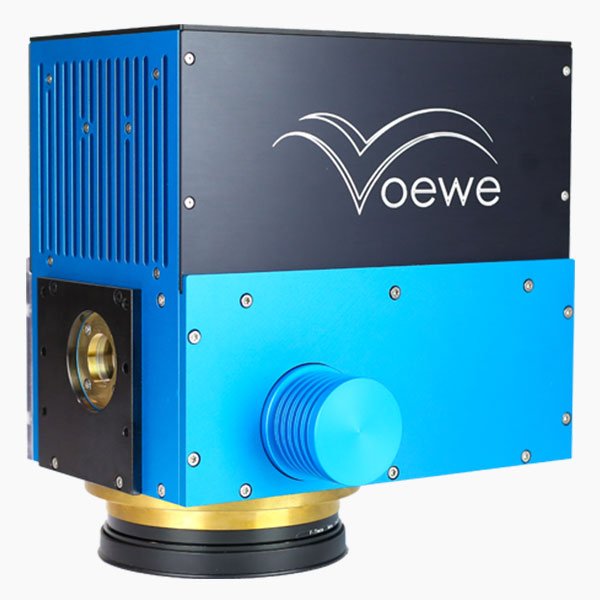

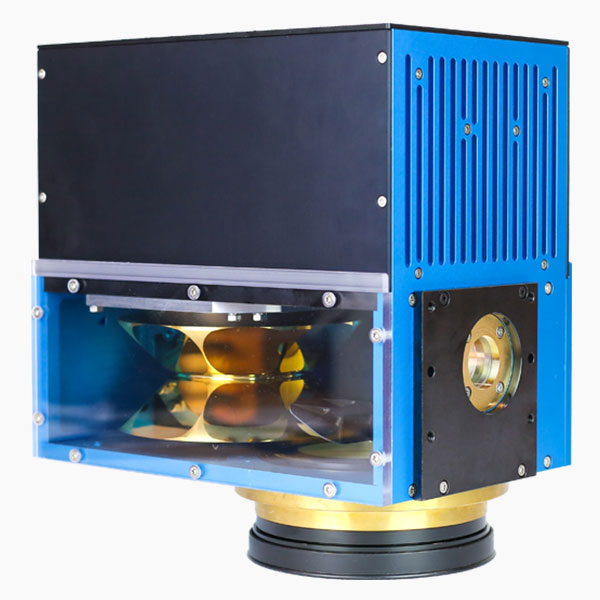

- MOEWE’s polygon mirror scanners (PM) are designed

for ultra-fast high-power laser processing. The system

is realized as two-dimensional beam deflection unit

available for 2D and 2.5D processing.

KEY FEATURES

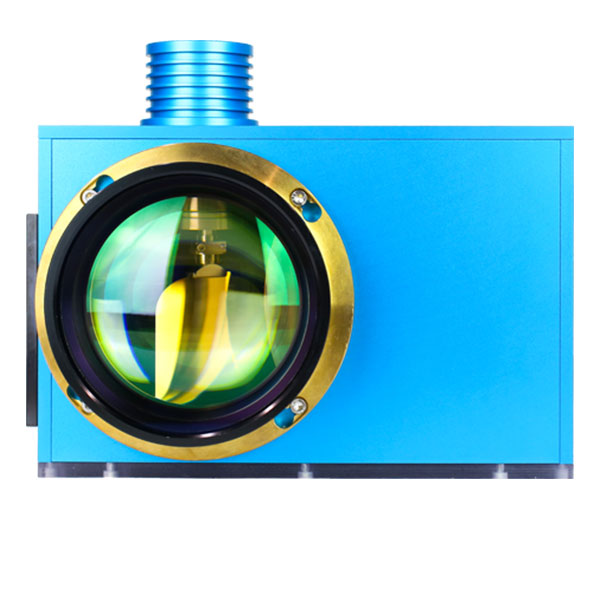

- Patented low distortion double polygon mirror

- Ultra-fast scan speeds on the entire scanning field (no acceleration loss)

- Full digital, FPGA on-board data processing

- Bitmap graphics up to 32-bit resolution

- Real-time laser switching for highest accuracy

- Special feature: UV and VIS option, very good focusability, high precision option, combination with DLIP. Integrated gray value processing by means of real-time control (PM 600)

- Power range: Power > 1 kW

- Aperture: 30 mm

- Processing mode: CW + pulsed + ultra short pulsed

Your advantages

- Two-dimensional beam deflection allows standalone utilization or machine integration (axis, rollto-roll)

- Multiple digital and analog I/O connectors, Ethernet for communication, encoding, process control

- Applications: universal (Marking, Microstructuring, Micromachining, LIFT, …) 2,5 D Engraving (PM600)

Options and variants

Optics

- Changeable f-theta lenses (standard or customized)

- Optics datasheet for suitable f-thetas available

Hardware

- Encoder IO for treating moving substates

- Fast laser trigger outputs TTL and anlogue

Software

- Parameter, bitmap graphics mode

- Up to 32-bit greyscale processing, engraving 2.5D

- Synchronization of multiple scanners

- Real time shifter for dynamic processing

Datasheet PM series

What our clients say

★★★★★

I’m very satisfied with high robustness of PM-300, and in specially, strong and kind custom support for our process.

I’m very satisfied with high robustness of PM-300, and in specially, strong and kind custom support for our process.

★★★★★

Extremely fast deflection and precision of the polygon scanner compared to other scaners is remarkable. Very good customer support, quick assistance and satisfied with everything so far.

Extremely fast deflection and precision of the polygon scanner compared to other scaners is remarkable. Very good customer support, quick assistance and satisfied with everything so far.

MOEWE solution completely new markets for laser machining can be opened up and will be an innovation leader frawing global attentionin the hig-end filed.

★★★★★

Very good performance product, active & kind supports, detailed and well-made manual of product.

Very good performance product, active & kind supports, detailed and well-made manual of product.

Unique functionality. Patented design and real-time data processing

Double reflection eliminates the fluctuations of the reflection point as a fundamental problem of polygon mirrors. In connection with a time marker and an extremely fast correction of manufacturing tolerances by an integrated FPGA (200 MHz) the polygon scanner system of MOEWE is extremely accurate.

For optimal results. Large clear aperture.

The free aperture of 30 mm, which is extremely large for a compact polygon scanner with a mass of only 13 kg, allows the use of large laser beam diameters. Thus, very small focus diameters can be achieved. With a focal length of 270 mm, approx. 25 µm are obtained for a single-mode fiber laser in the NIR wavelength range at a scan length of 160 mm.

Incredibly fast. Scanning speed >1,000 m/s possible.

With the increasing power of ultra-short pulse lasers, ultra-fast beam deflection with polygon scanners is useful to achieve the high productivity that such lasers allow, even at high quality. USP lasers with a single pulse frequency of > 10 MHz can still be precisely controlled with our device.

Unterstützt von

What a typical cooperation with us looks like

Point 1

Direct customer inquiry via the website, by mail or via phone.

Point 2

Clarification of detailed customer needs, the process and technological approach.

Point 3

An offer is prepared by sales department.

Point 4

If no questions left, customer places an order.

Point 5

Payment agreement about down and final payment.

- Our turn: Production,calibration and shipment

- Customer can easily integrate the Scanner on its own

Point 6

Training on our polygon scanner on MOEWE site in Mittweida/Germany or as an online course.

Point 7

Follow-up on specific requests possible, usually by mail, via phone or online meeting, if necessary.

Your contact: Manja Hänsel – Communications